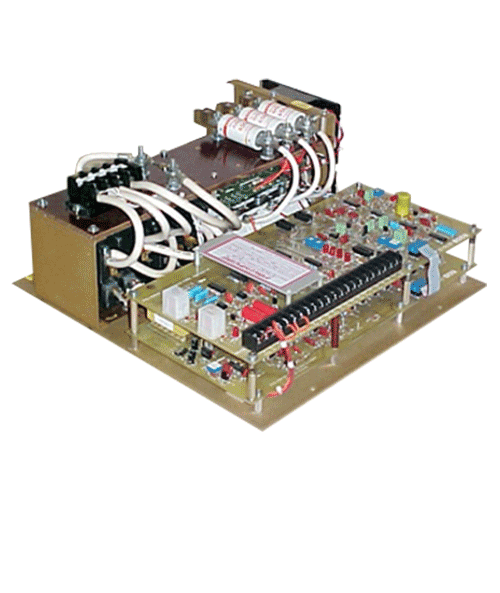

The HP series of DC motor controls provide accurate speed regulation, repeatable speed settings and large power capacity in a compact package. Designed for high stress industrial applications, the HP operates on three phase 230 or 460 VAC input. A full-wave, six SCR output power section delivers six pulses for every AC input cycle. This provides for smooth and cool motor operation, even in high torque, low speed applications.

The HP series is available in three basic types:

- BHP for forward operation without armature contactors

- FHP for forward operation with one armature contactor

- RHP for forward and reverse operation with two armature contactors and dynamic braking

Ratings:

Ratings:

3 – 20 HP

Input: 230 VAC + 10%, 3Ø, 50/60Hz + 5%

Output: 0-240 VDC armature, 150VDC field

(240 VDC field optional)

Ratings:

3 – 40 HP

Input: 460 VAC + 10%, 3Ø, 50/60Hz + 5%

Output: 0-500 VDC armature, 300VDC field

Overload Capacity:

150% for one minute

Instantaneous Overcurrent trip:

Preset for 260% of rated current

Acceleration / Deceleration:

Independently adjustable from 0.6 to 28 seconds.

Torque (current) limit:

Adjustable from 0 to 200% of rating.

Minimum speed:

Adjustable from 0 to 10% of rated output voltage.

Maximum speed:

Adjustable from 75 to 105% of rated output voltage.

IR Compensation:

Adjustable from 0 to 10% boost.

Speed Regulation:

(percent of base speed with 95% load change)

+ 1.0% with armature feedback

+ 0.1% with tachometer feedback.

Speed Command Input:

4 – 20 milliamp or 0-6 VDC.

Tachometer feedback input:

175 or 2500 rpm motors with a 50 VDC/1000 rpm tachometer standard, other ranges available.

Dimensions (open chassis):

3 – 10 HP, 230 VAC:

14″ (W) x 14″ (H) x 5-5/8″ (D)

15 – 20 HP, 230 VAC:

14″ (W) x 15-1/2″ (H) x 5-5/8″ (D)

5 – 25 HP, 460 VAC:

14″ (W) x 14″ (H) x 7″ (D)

30 – 40 HP, 460 VAC:

14″ (W) x 15-1/2″ (H) x 7″ (D)

Weight:

open chasis: 20 lbs

HP Series Model Selection Table |

||||

|---|---|---|---|---|

| HP | Input | BHP Model | FHP Model | RHP Model |

| 3 | 230 VAC | BHP-30 | FHP-30 | RHP-30 |

| 3 | 460 VAC | BHP-31 | FHP-31 | RHP-31 |

| 5 | 230 VAC | BHP-50 | FHP-50 | RHP-50 |

| 5 | 460 VAC | BHP-51 | FHP-51 | RHP-51 |

| 7.5 | 230 VAC | BHP-75 | FHP-75 | RHP-75 |

| 7.5 | 460 VAC | BHP-76 | FHP-76 | RHP-76 |

| 10 | 230 VAC | BHP-100 | FHP-100 | RHP-100 |

| 10 | 460 VAC | BHP-101 | FHP-101 | RHP-101 |

| 15 | 230 VAC | BHP-150 | FHP-150 | RHP-150 |

| 15 | 460 VAC | BHP-151 | FHP-151 | RHP-151 |

| 20 | 230 VAC | BHP-200 | FHP-200 | RHP-200 |

| 20 | 460 VAC | BHP-201 | FHP-201 | RHP-201 |

| 25 | 460 VAC | BHP-251 | FHP-251 | RHP-251 |

| 30 | 460 VAC | BHP-301 | FHP-301 | RHP-301 |

| 40 | 460 VAC | BHP-401 | FHP-401 | RHP-401 |

FEATURES:

- Current sensing shunt provides a low-voltage signal proportional to the armature current for current monitoring circuits

- Power-on timer ensures power supply stability before startup by delaying startup by 200 milliseconds

- Optional automatic reversing remembers a reverse command and causes the motor to dynamically brake to zero speed, then reverse without an additional start command

- CMOS logic provides high noise immunity and low power consumption

- Built-in signal isolation permits connecting the speed pot control common to earth ground

- Digital ramp generator prevents phase mismatch between lines and eliminates ramp balance adjustments

- Line isolation provides impedance-isolated armature feedback and transformer-isolated shunt feedback signals

- Reed relays reduce electrical noise

- Latching network allows use of standard momentary contact push buttons for operator commands

- 50 or 60 Hz input selection

- Contactor timing and interlocks ensure zero current switching in models with contactors, extending contactor life

- LED indicators show phase loss protection, low line voltage protection, torque limit and forward or reverse operation

- Phase-insensitive AC input

- Control transformer (460 VAC models only)

- Independently adjustable acceleration and deceleration ramps

- Instantaneous overcurrent trip with LED fault indicator

- Anti-plug protection prevents start-up or reversal of the drive until the motor armature reaches zero speed

- Tachometer feedback input for 1750 or 2500 rpm motors with a 50 VDC/1000 rpm tach

- Remote/Local torque programming by jumper selection

- Speed command input of 4-20 milliamp or 0-6 VDC

- Standard options to meet most requirements

Options (cost extra)

| Option | Notes | Code |

|---|---|---|

| Field Economizing | FHP and RHP only | FE |

| Inverse Timed Shutdown | Electronic motor overload | ITS |

| Change to 240V Field |

(230V Units Only) | 240 |

| Speed Indicating Meter (Shipped Loose) |

3 1/2 inch Analog | SML |

| Speed Indicating Meter (Door Mounted) |

Analog, Installed on NEMA 12 option | SME |

| External Torque Programming |

ETP | |

| Adjustable Jog – Note 2 |

J2 | |

| Automatic Reversing (RHP only) |

Allows motor to reverse without a stop command | AR |

| Change to 50Hz Operation |

50 | |

| Preset Speeds – Note 3 | 0 Internal, 7 External | PS0 |

| 3 Internal, 1 External | PS3 | |

| 4 Internal, 0 External | PS4 | |

| 6 Internal, 1 External | PS6 | |

| 7 Internal, 0 External | PS7 | |

| Armature Voltage Follower |

0-90 VDC | VF1 |

| 0-180 VDC | VF1 | |

| 0-240 VDC | VF1 | |

| 0-500 VDC | VF2 | |

| External Signal Follower |

1-5 mA DC | SF1 |

| 4-20 mA DC | SF2 | |

| 10-50 mA DC | SF3 | |

| 0-6 VDC | SF4 | |

| 0-10 VDC | SF4 | |

| Tachometer Follower |

0-20 VDC | TF1 |

| 0-65 VDC | TF2 | |

| 0-200 VCD | TF3 | |

| 0-75 VAC | TF2 | |

| 0-230 VAC | TF3 | |

| Tachometer Feedback – Note 1(50 VDC/1000 rpm) |

(BHP, FHP) 1750 rpm | T2 |

| (BHP, FHP) 2400 rpm |

T3 | |

| (RHP) 1750 rpm |

TR2 | |

| (RHP) 2400 rpm |

TR3 | |

| Dynamic Braking (Standard on RHP) |

3-10hp (230V) | D1 |

| 15-20hp (230V) | D2 | |

| 3-15hp (460V) | D3 | |

| 20-40hp (460V) | D4 | |

| NEMA 12 Enclosure |

3-10hp (230V) & 3-20hp (460V) | E1 |

| 15hp (230V) & 25-30hp (460V) | E2 | |

| 20hp (230V) | E3 | |

| 40hp (460V) | E4 | |

| Circuit Breaker (Door Mounted) |

3-10hp (230V) & 3-20hp (460V) |

CB1 |

| 15hp (230V) & 25-30hp (460V) | CB2 | |

| 20hp (230V) | CB3 | |

| 40hp (460V) | CB4 | |

| Local Operator Control Station(Installed on NEMA 12 Option) |

Start, Stop, Run/Jog, Speed Adjust | LOC-1 |

| Start, Stop, Run/Jog, Manual/Auto, Speed Adjust | LOC-2 | |

| Start, Stop, Run/Jog, Fwd/Rev, Speed Adjust | LOC-3 | |

| Start, Stop, Run/Jog, Manual/Auto, Fwd/Rev, Speed Adjust | LOC-4 | |

| Remote Operator Control Station(Separate NEMA 12 Enclosure) |

Start, Stop, Run/Jog, Speed Adjust | ROC-1 |

| Start,Stop, Run/Jog, Manual/Auto, Speed Adjust | ROC-2 | |

| Start,Stop, Run/Jog, Fwd/Rev, Speed Adjust | ROC-3 | |

| Start,Stop, Run/Jog, Manual/Auto, Fwd/Rev, Speed Adjust | ROC-4 | |

| Field Loss Protection |

150 VDC field | FL1 |

| 240 VDC field | FL2 | |

| 300 VDC field | FL3 |

Note 1: Tachometer feedback option does not include a tachometer generator.

Note 2: Jog speed option cannot be supplied with any preset speed option.

Note 3: Preset speed options do not include the external speed potentiometers.

Note 4: Some pre-designed option combinations are mutually exclusive.

Others may be obtained by custom engineering from Polyspede.